Tønsberg

Den Magiske Fabrikken

2008 / 2013 / 2023

Energi

5,000 Nm³/h

The biogas facility in Tønsberg is called “Den Magiske Fabrikken” – a fitting name for a plant that truly creates circular magic. Here, recycling has been taken to the next level, where everything that can have a second life, does.

We have had the privilege of following and contributing to the development of Den Magiske Fabrikken over many years, a partnership we are proud of. Through the delivery of three Malmberg COMPACT units, we have been part of turning visions of a circular economy into reality.

The facility produces biogas, biofertilizer, and green carbon dioxide by recycling food waste and manure from eastern Norway and Vestfold.

Quick facts about Den Magiske Fabrikken

Behandlingskapacitet

- 70 000 tonnes food waste

- 75 000 tonnes manure

Produktion

- 15 million Nm3 biometan per year

- 180,000 m³ of biofertiliser per year

Greve Biogass is the result of a collaboration between the Grenland area and Vestfold County to establish a joint biogas facility. It is a municipally owned company, with ownership shared between Vesar AS, the municipalities of Vestfold (Horten, Holmestrand, Hof, Andebu), Tønsberg wastewater treatment plant (IKS), and the Grenland municipalities (Porsgrunn, Skien, Kragerø, Siljan, and Bamble).

Vestfold consists of 14 municipalities with a total population of approximately 280.000.

Grenland consists of 6 municipalities with a total population of around 120.000.

From vision to reality

In 2008, the planning of a biogas facility in Norway began, with the goal of creating a sustainable energy source from local food waste and sludge. An important question early in the process was whether biogas could be used as fuel for public transport buses. After investigation and discussion, the county administration gave its approval.

In 2013, Greve Biogass was established. A municipally owned company responsible for converting local waste products into biogas, biofertilizer, and green carbon dioxide.

To secure the supply of substrate, a collaboration was developed with farmers in Vestfold. Manure from the farms is delivered to the facility in exchange for recycled biofertilizer. The collaboration was formalized through joint financial reviews and agreements that ensure long-term profitability and sustainability for all parties involved.

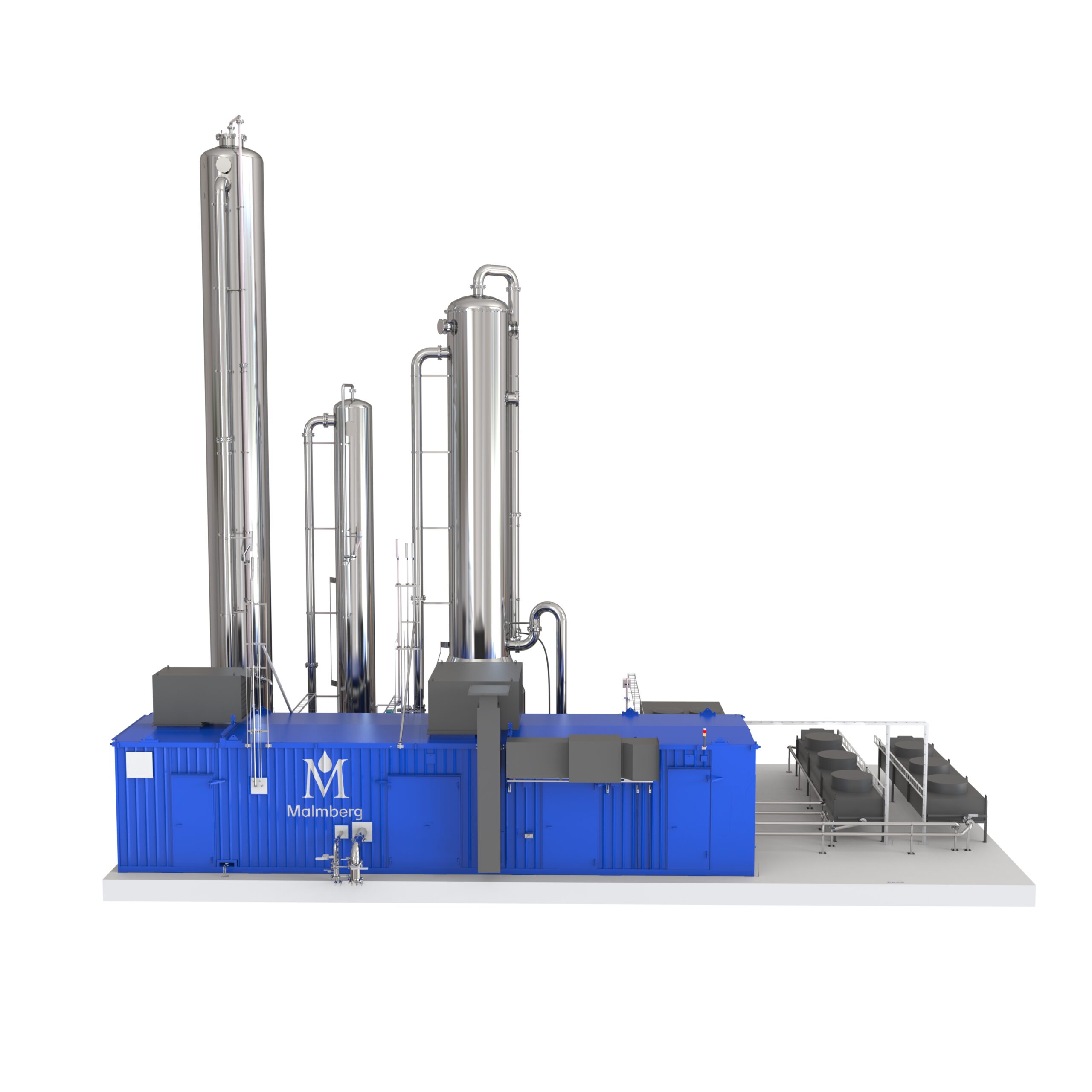

A trio of Malmberg COMPACT

Our collaboration with Den Magiske Fabrikken began in 2014 with the delivery of their first upgrading facility, a Malmberg COMPACT GR14R. The facility consistently produces 98–98.5% biomethane and has delivered results that exceeded expectations.

“Today, we are producing well above what we had anticipated. We didn’t quite expect it to go this well.”

— Knut Olav Furuseth, Hjellnes Consult

Just three years later, in 2017, another Malmberg COMPACT GR14 was installed, with the capacity to upgrade 1,200 Nm³/h.

In 2023, Den Magiske Fabrikken took the next step and decided to further expand production. Once again, they chose Malmberg, this time ordering a Malmberg COMPACT GR20. The facility has the capacity to upgrade 2,400 Nm³/h of biogas to biomethane and includes a regenerative thermal oxidizer (RTO) that reduces odour, carbon consumption, and air pollution.

Together, the three Malmberg COMPACT units now produce about 5,000 Nm³/h of biomethane – a major gain for both the environment and the economy.

Den Magiske Fabrikken’s circular solutions

Biogas upgrading

The upgraded biogas is used as a renewable fuel and replaces fossil fuels in both heavy and light vehicles. The biogas is delivered as compressed biogas (CBG) and liquefied biogas (LBG) and is used to power trucks, buses, and other vehicles.

Biofertilizer

The residual product from Den Magiske Fabrikken is a clear example of a circular economy in practice. By returning nutrients from food waste and manure to agriculture, the nutrient cycle is closed and sustainable food production is promoted. The nutrients are preserved throughout the biogas process and remain in the biofertilizer, making it a sustainable alternative to chemical fertilizers. In addition, the biofertilizer adds organic material and fibres that improve soil structure and increase resilience to drought and heavy rain.

Green carbon dioxide (CO₂)

Next to the biogas facility, a pilot greenhouse was launched in 2018. The greenhouse uses captured green carbon dioxide and biogas-based biofertilizer to grow tomatoes.