When you invest in a facility from Malmberg, it represents a long-term commitment to your business. That’s why we offer comprehensive service and aftermarket support throughout the entire lifecycle of your facility.

Our service team is here to ensure that your facility operates smoothly and efficiently. You can reach our efficient HelpDesk 24/7 to resolve issues and minimize downtime. For us, it’s about building trust and delivering real results that make a difference for your business and your future.

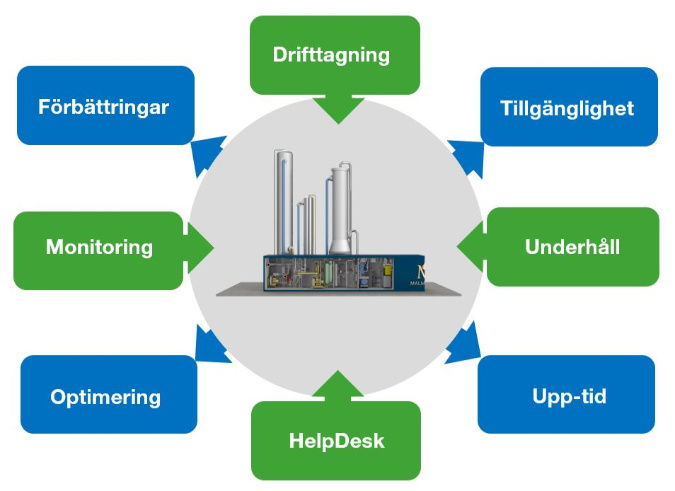

Malmberg Maintenance Concept

Ensure that your biogas upgrading system has maximum availability. A production stoppage can be critical, and every hour of downtime results in significant revenue loss. With a Malmberg Maintenance Concept agreement, you and your facility are always in good hands and treated with the highest priority.

Get a Malmberg Maintenance Concept (MMC)

- Planned maintenance work

- 24/7 HelpDesk support

- A single point of contact

- Direct support for mechanical or process-related issues

- Online monitoring for troubleshooting

- Critical spare parts in stock

Commissioning

Our team of mechanical, electrical, and automation technicians handles the commissioning of our facilities. These are the same technicians who also provide our service and support, ensuring they have the experience and background specific to the characteristics of each facility.

Maintenance

All facilities with a Malmberg Maintenance Concept (MMC) agreement have a regular maintenance schedule carried out by our own team of Malmberg Service Technicians.

HelpDesk

Our facilities are equipped with a modern and user-friendly automation system that allows you to monitor the process both on-site and off-site. With a Malmberg Maintenance Concept (MMC) agreement, the facility operator has an exclusive HelpDesk code to use 24/7, where they receive direct assistance from a service technician remotely.

Monitoring

Thanks to our control system, Malmberg feniX™, installed in every facility, we can remotely monitor, troubleshoot, or optimize biogas production to resolve operational issues.

aCurve

An optimization tool used in facilities to monitor their performance and gain an overview of their efficiency.

Learn More